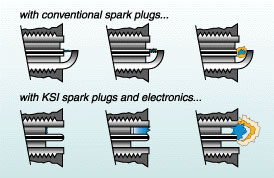

Using the same energy input, a KSI™ system generates an “ignition kernel” dramatically larger than a conventional ignition system spark, which produces major improvements in engine operation.

The Kinetic Spark Ignition Solution

History of KSI

Most current systems do a fairly good job with today’s spark-ignited (i.e., non-diesel) engines.

However, there is considerable pressure from governments and the market to increase engine efficiency and reduce polluting emissions. Some of the systems discussed above can improve ignition in one or more ways, but always with one or more penalties, such as excessive energy consumption, high cost, bulky size, or limited performance range.

In 1990, scientists from Princeton University and the Princeton Plasma Physics Lab began to apply advances in plasma physics to spark-ignited internal combustion engines. After several years of progress, the Princeton team demonstrated and patented a breakthrough concept they called “Kinetic Spark Ignition™” (KSI™). Knite Inc. was formed in 1996 to commercialize KSI and started operations in 1997.

Since 1997, Knite has worked to reduce the concept technology to a practical, long-lived, commercial system. Knite has the sole rights to the original Princeton patents and

also owns several additional U.S. patents and others are pending. Outside the U.S., Knite has been awarded 42 additional patents in 24 countries and other jurisdictions—such as the European Union—and have six more pending.

Description of the KSI System

The KSI system consists of a proprietary electronic system and an igniter. The igniter

has a construction similar to a conventional spark plug and can be inserted into existing spark plug holes in present day engines. The system can be manufactured easily in existing facilities at costs comparable to the costs of current factory-installed systems.

The electronic system generates a high voltage discharge that creates a “seed” plasma between two electrodes inside the proprietary igniter. This discharge acts as a switch to allow a capacitor to deliver energy directly into the discharge, bypassing the coil. This second pulse of low-voltage, high-current electricity “grows” the seed plasma. The plasma is accelerated by an electro-magnetic force (“the Lorentz force”) along the electrodes, “ejecting” it into the air/fuel mixture in the cylinder.

The plasma (spark) is much more powerful than a conventional spark. It initially ignites a much larger portion of the air/fuel mixture, and the combustion expands more rapidly in the cylinder than is possible with a conventional spark. The end result is a faster, more uniform, and more complete burn of the air/fuel mixture, reducing air-polluting emissions and increasing efficiency.

The conversion of electrical energy into plasma by the KSI system is very efficient—over 90 percent—in contrast to the low efficiency of conventional ignition systems.

In summary, the superiority of the KSI system over existing and other proposed ignition systems is due to:

- the very large spark or plasma, 100 times as powerful as a conventional spark, which can ignite a very lean air/fuel mixture, or a highly compressed mixture, that would be hard to ignite with a conventional spark;

- a short spark duration, which allows precise ignition timing and higher engine speeds;

- movement of the plasma along the electrode, which reduces the erosion of the electrode and speeds the combustion process;

- a design that is economical to produce;

- a longer igniter life than other new “large spark” systems, such as the other pulsed direct current systems or the exotic systems described above;

- compact system design that can be fitted into limited space;

- efficient design that requires no more power than existing systems and allows retrofitting in existing engines;

- plasma behaviour conrolable by the engine ECU.

The KSI system improves the combustion process, resulting in:

- more complete combustion, thus lowering harmful emissions (see “Green Solutions” below),

- improved fuel efficiency, increasing miles per gallon,

- smoother engine performance at all speeds and loads,

- application in most engine markets.

Knite’s KSI system opens the door to solving engine performance problems that were once considered impractical or impossible with conventional ignition technologies.

For example, KSI can enhance the performance of advanced engine technologies using Gasoline Direct Injection (GDI), Exhaust Gas Recirculation and the use of alternative fuels.

In GDI engines, the fuel is injected directly into the cylinder, where it mixes with air before being ignited. GDI engines have a great potential for enhanced performance, but they do not perform well with conventional ignition systems. Tests have shown that the Kinetic Spark Ignition system gives GDI engines substantially improved performance.